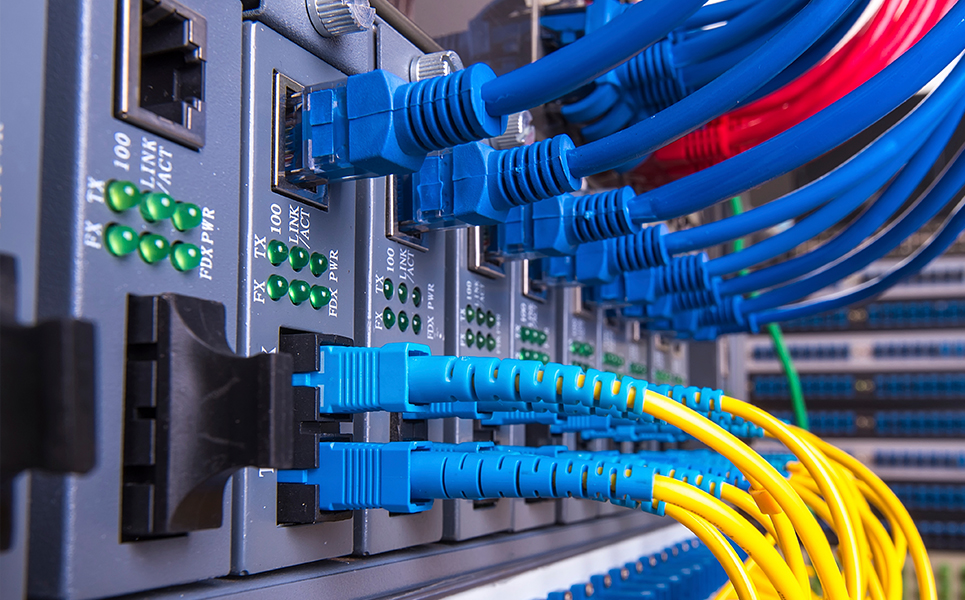

Wire and cable

PVC insulation materials have good reliability and safety properties, including chemical resistance, wear resistance, flame retardancy and good insulation properties. Compared with other insulation materials, it has the advantages of low price, easy processing and good insulation performance.

Medical industry

Modified pvc and PE plastics can be widely used to make blood storage bags, blood transfusion bags, as well as blood ducts, artificial peritoneum, artificial urethra, bag artificial lung, cardiac catheters and artificial heart and other products. In addition, the composite membrane composed of LDPE, PA and PE has the advantages of pvc and PP bags and is widely used.

Daily necessities industry

Daily plastic products generally use PE and PP raw materials, such as wash basin, iron bucket, laundry pool, plastic anvil, plastic chair but mineral water bottle, transparent medicine bottle is better to choose PET, bright gift packaging box tank, decoration design lamp, wall lamp, ceiling lamp plastic components, often used PS.

Electronic and electrical industry

PC plastics are often used in LED lamps, monitors, camera shells and other high-grade electronic products. PP plastics are often used in electronic products such as Jack, plug and other spare parts, but also can be used in the manufacture of mobile phone shells. PE plastics are often used in electronic products such as sealing rings, gaskets and other parts, but also can be used in the manufacture of vehicle electrical accessories. POM plastics are often used in the manufacture of switches, plug-ins, sliders and other precision spare parts in electronic products. PA plastics are often used in the manufacture of bearings, gears, connectors and so on in electronic products.

Automobile industry

The main plastics commonly used in automobile interior and exterior decoration parts are PP class, PC/ ABS class, ABS class, PE class, PA class and POM, among which the largest amount is PP material.

New energy

New energy power battery structure: support, frame, end plate, optional materials are flame retardant PPE, PC/ABS alloy and flame retardant reinforced PA. PPE density 1.10, PC ≤ ABS density 1.2, enhanced flame retardant PA1.58g/cm, from the point of view of weight loss, the main choice of flame retardant PPE.

Home appliance industry

General plastics for household appliances: ABS, HIPS, GPPS, PP, etc.; high surface requirements: color, finish, luster, hardness, printing properties, etc.; better mechanical properties, thermal properties, aging resistance; flame retardancy, electrical insulation properties; better processing properties, dimensional stability; cheap price.

CONTACT US

CONTACT US